To design a set of the most efficient manufacturing processes for parts to create the maximum profit for customer. Once a customer's order is received by our business department, a cross functional project team, which consists of R&D, manufacturing, quality-control and production-planning, will be set up immediately. They will study in detail with customer based on customer's needs, from raw material supply and distribution, production lines allocation, processing conditions, engineering changes, packaging, shipping, to delivery methods to make the most efficient production plan for the product and to reach the goal of providing customers the highest quality products with the best timing.

To implement an ISO quality management system that encompasses all the way from customer or supplier feeding material inspection, first article inspection, process inspection, touring inspection, finished product inspection, to shipment inspection and to plan and execute the annual inspection for instruments or equipment and self-inspection schedule to ensure the precision and performance of the instruments or equipment. Our quality control department adheres to the policy of quality first and executes quality inspections at each stage vigorously and truthfully to provide the best product quality for customer's need.

Warehouse Management: to adapt appropriate storage methods or protective measures for raw materials shipped into the plant, outsourcing work-pieces, and semi-finished and finished products etc. to ensure their quality, avoid pollution of the environment, endanger the health and safety of colleagues, and maintain correct inventory information to supply production and make delivery in time. As for production equipment and facility fixture such as tools, fixtures, and molds etc. Warehouse management performs effective management for their transfer, storage, use, maintenance, and inventory etc. to maintain their service life and precision to ensure the quality of mass production.

Our manufacturing department is using the SOLIDWORKS-SOLIDCAM manufacturing integration platform. Our production-line and special machining process have greatly enhanced for those applications. When it is matched up with an internal database built by our R&D department, it allows us to perform product development from prototype design, analysis, all the way to manufacturing at one shot.

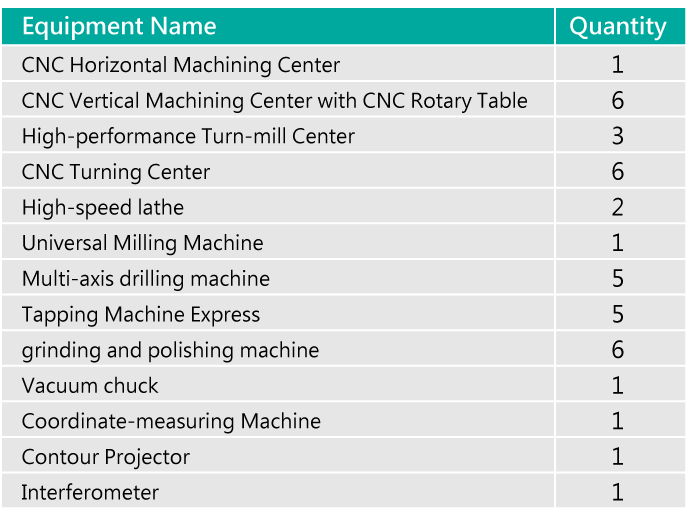

Our team can provide multiplicity service under customer's request or place, such as CNC lathe, machining center, and medical equipment…etc. We have confidence in professed assembling with high quality.